The Chemistry of Delta-8 Production: Understanding the Key Factors and Processes

Delta-8 THC, or delta-8 tetrahydrocannabinol, is a psychoactive compound that occurs naturally in cannabis. It is similar to delta-9 THC, the primary psychoactive compound in cannabis, but it has a slightly different molecular structure.

Delta-8 Production has gained popularity recently due to its reported milder psychoactive effects and potential health benefits, and as a result, many are interested in Delta-8 production.

In this post, we will explore the chemistry of delta-8 production and the key factors and processes involved in producing it.

Gold + Silver Paradise Mix

Original price was: $154.98.$68.99Current price is: $68.99.

Or Subscribe and Save 30%

Gold + Silver Combo Fruity Mix

Original price was: $154.98.$68.99Current price is: $68.99.

Or Subscribe and Save 30%

Understand the delta-8 chemistry

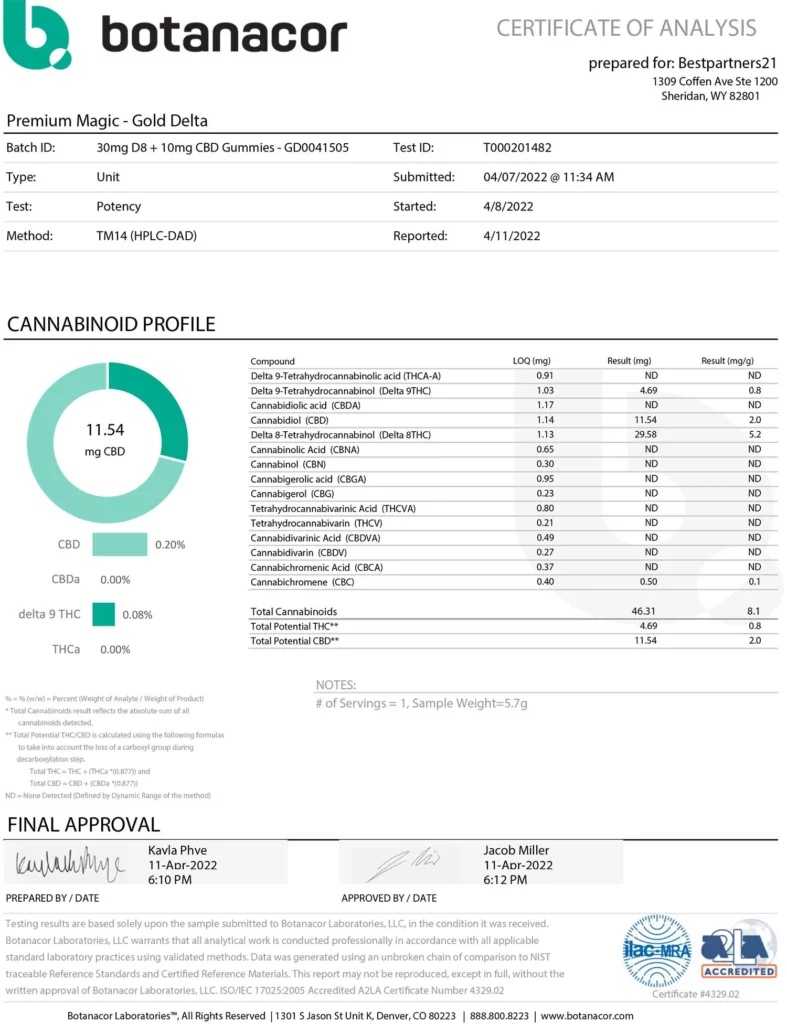

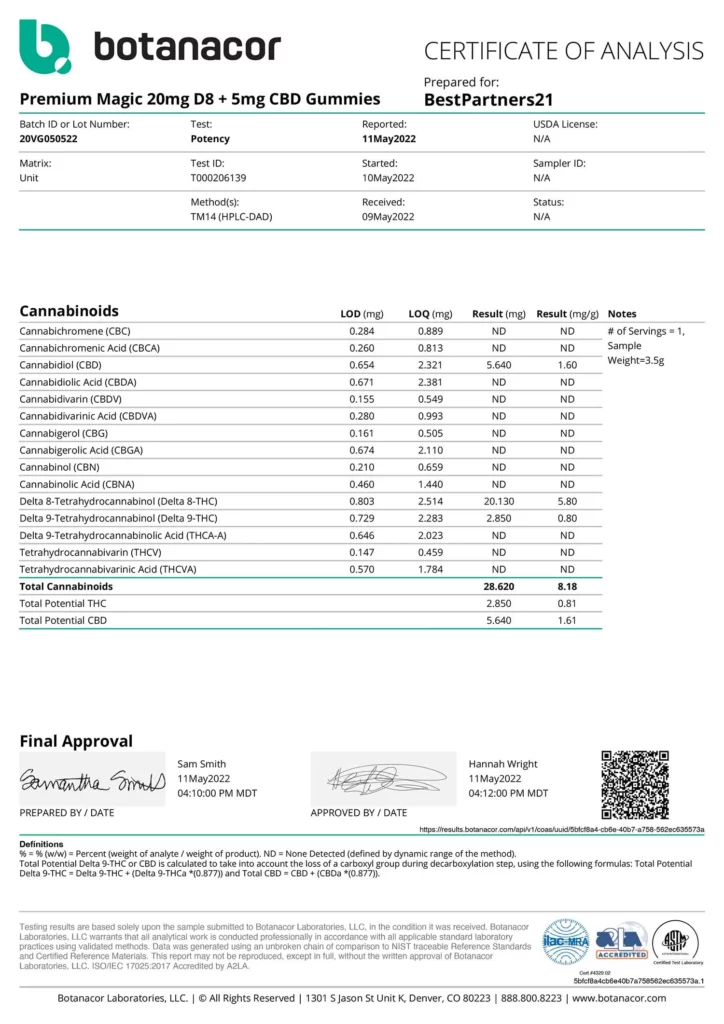

Delta-8 THC can be produced from cannabidiol (CBD), which is a non-psychoactive compound found in cannabis. The process involves a chemical reaction that converts CBD into delta-8 THC.

CBD manufacturing and how it differs from Delta-8 production

CBD manufacturing and delta-8 THC manufacturing differ in their final product and the Delta-8 Production process involved. CBD manufacturing involves extracting cannabidiol (CBD) from the hemp plant, which is then used to make various products, including oils, edibles, topicals, and more.

For Delta-8 Production, CBD is converted into delta-8 THC through a chemical process, which is a psychoactive cannabinoid similar to delta-9 THC, the primary psychoactive compound in cannabis.

How to make tetrahydrocannabinol?

There are several methods of producing delta-8 THC, but they all involve manipulating the chemical structure of CBD. Here are some of the key factors and processes involved in Delta-8 production:

Quality of the starting material

The first factor that affects the Delta-8 production is the quality of the starting material, which is typically CBD extract. High-quality CBD extract will produce higher yields and purer delta-8 THC. The CBD extract should be free of impurities and contaminants that could interfere with the chemical reaction.

Chemical reagents

The chemical reaction that converts CBD into delta-8 THC requires the use of specific chemical reagents. The most common reagents used are an acid catalyst, such as hydrochloric acid or sulfuric acid, and a reducing agent, such as zinc or palladium. The choice of reagents and their purity can significantly affect the yield and quality of delta-8 THC.

Reaction conditions

The reaction conditions, such as temperature, pressure, and time, also play a critical role in the Delta-8 production. The reaction typically takes place under acidic conditions and at elevated temperatures, usually around 100-120°C. The reaction time can range from a few hours to several days, depending on the specific method and reagents used.

Purification

Once the reaction is complete, the crude delta-8 THC product must be purified to remove any impurities or byproducts. The purification process typically involves multiple steps, such as extraction, distillation, and chromatography. The purity of the final product is essential for safety and efficacy.

It is worth noting that Delta-8 production from CBD is not a straightforward process and can be challenging to achieve high yields and purity. Additionally, the legality of delta-8 THC varies depending on the jurisdiction, and producers should consult with local regulations before producing and distributing delta-8 THC products.

Conclusion

In conclusion, producing delta-8 THC involves a complex chemical process that requires careful attention to the quality of the starting material, the selection of reagents, reaction conditions, and purification methods.

Understanding the chemistry of delta-8 THC production is crucial for the safe and effective production of delta-8 THC products. However, it is important to note that producing and distributing delta-8 THC products may not be legal in all jurisdictions, and producers should always consult with local regulations before starting any manufacturing process.