The Ethics and Sustainability of Delta-8 Production: Balancing Quality and Responsibility

At the heart of any responsible CBD manufacturing process is a commitment to ethical and sustainable practices. This is especially true when it comes to delta-8 production, a variant of tetrahydrocannabinol that has become increasingly popular in recent years due to its purported therapeutic benefits.

As the demand for delta-8 continues to grow, it is imperative that manufacturers prioritize quality and responsibility in delta-8 production processes to ensure that consumers can trust the safety and efficacy of the products they are purchasing.

Delta-8 Gummies – Gold Paradise Mix

Original price was: $82.99.$38.99Current price is: $38.99.

Or Subscribe and Save 30%

Silver Paradise Mix

Original price was: $68.99.$33.99Current price is: $33.99.

Or Subscribe and Save 30%

Delta-8 Chemistry: Understanding the Process of delta-8 production

Delta-8 is a cannabinoid that occurs naturally in very low concentrations in cannabis plants. As a result, producing delta-8 requires a complex chemical process that involves converting delta-9, the more abundant variant of tetrahydrocannabinol, into delta-8.

The process typically involves a series of chemical reactions, including isomerization, distillation, and chromatography, that ultimately result in a concentrated delta-8 extract.

One of the primary challenges in producing delta-8 is achieving high levels of purity while also minimizing the presence of harmful impurities. This requires a great deal of expertise and precision, as well as a commitment to using high-quality starting materials and state-of-the-art equipment.

At every stage of the delta-8 production process, it is important to carefully monitor the chemical reactions and take steps to ensure that the final product is of the highest possible quality.

Sustainability in Delta-8 Production: A Call to Action

While the production of delta-8 presents numerous challenges, it also offers an opportunity for manufacturers to prioritize sustainability and environmental responsibility.

This includes everything from using renewable energy sources to power production facilities to implementing sustainable waste management practices and minimizing the use of harmful chemicals and materials.

As the CBD industry continues to grow and evolve, there is a growing awareness of the need for sustainable practices across the entire supply chain. This includes not only the delta-8 production, but also the cultivation and harvesting of cannabis plants, the processing of raw materials, and the distribution and packaging of finished products.

By prioritizing sustainability and ethical practices at every step of the process, manufacturers can help ensure that the industry remains viable and responsible for years to come.

How to Make Tetrahydrocannabinol: A Step-by-Step Guide

For those interested in producing delta-8, it is important to understand the basics of tetrahydrocannabinol chemistry and the steps involved in producing high-quality delta-8 extracts. Here is a step-by-step guide to the process:

- Start with high-quality cannabis plants. The quality of the starting material will have a significant impact on the purity and potency of the final product.

- Extract delta-9 tetrahydrocannabinol using a solvent-based extraction process. This can be accomplished using a variety of solvents, including ethanol and butane.

- Convert delta-9 to delta-8 using a process called isomerization. This involves using a catalyst and heat to transform delta-9 into delta-8.

- Refine the delta-8 extract using distillation and chromatography. This will help remove impurities and ensure a high level of purity.

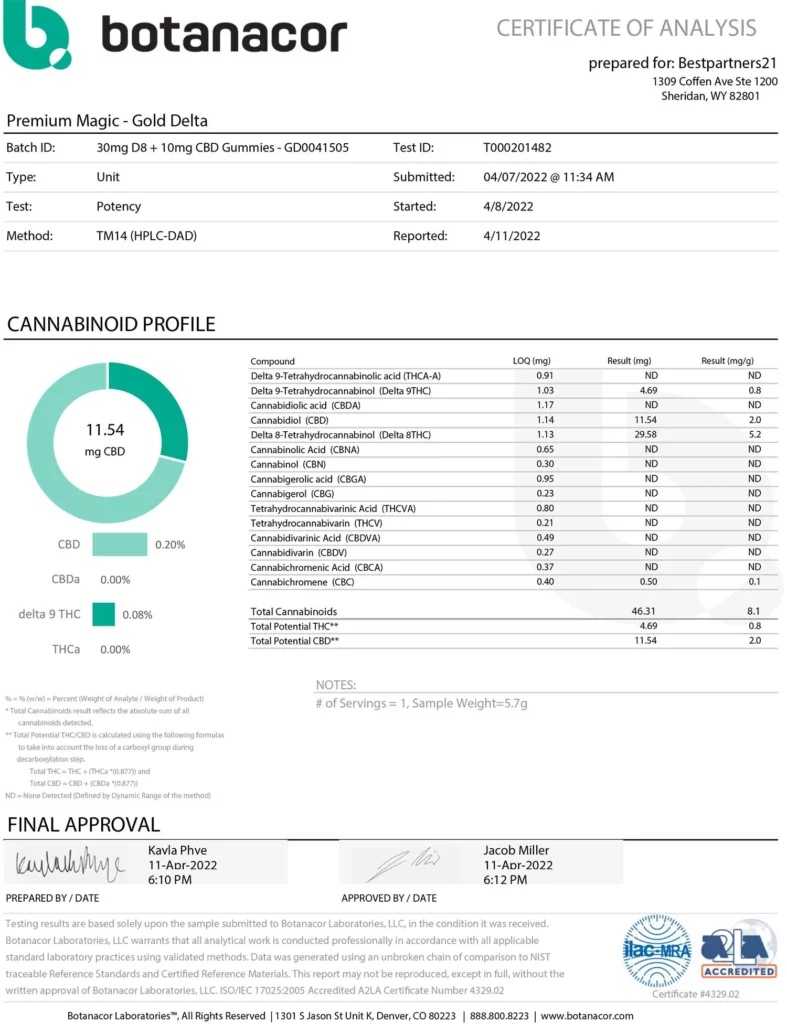

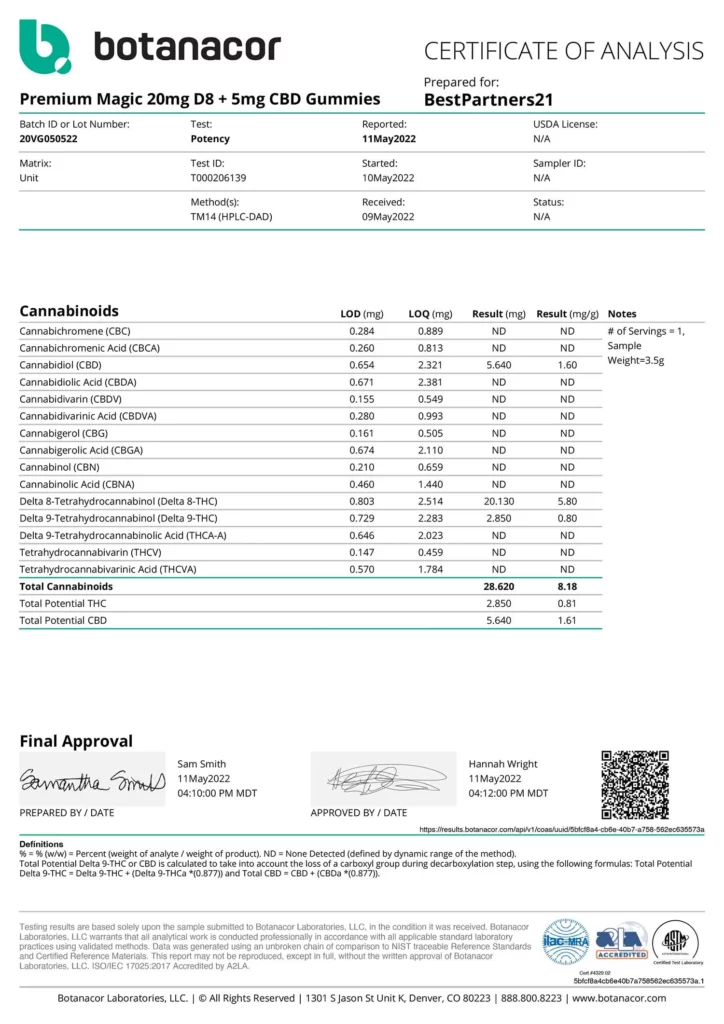

- Test the final product to ensure that it meets quality and safety standards. This may include testing for potency, purity, and the presence of harmful contaminants.

Prioritizing Ethics and Sustainability in Delta-8 Production

The process should not harm the environment

One of the most critical ethical considerations when producing delta-8 is ensuring that the production process does not harm the environment. Delta-8 is typically extracted from hemp plants, which are a sustainable crop that requires fewer resources to grow than other plants.

However, the extraction process can involve the use of solvents, which can have adverse effects on the environment if not handled correctly. Therefore, it is essential to use eco-friendly extraction methods and dispose of the solvents responsibly.

Using energy-efficient equipment and renewable energy sources

Another consideration is the use of energy-efficient equipment and renewable energy sources to power the delta-8 production process, which can significantly reduce the carbon footprint of the operation.

It should not harm the community

Another important ethical consideration when producing delta-8 is ensuring that the process does not harm the community. The delta-8 production process can involve the use of various chemicals and equipment, which can be hazardous if not handled correctly.

Therefore, it is essential to ensure that the workers are adequately trained and equipped with personal protective equipment to minimize the risk of accidents and exposure to harmful substances.

Follow local regulations

Additionally, it is crucial to follow local regulations and obtain the necessary permits to operate legally and minimize the impact of the production process on the surrounding community.

Sustainability

Sustainability also plays a significant role in the production of delta-8. The manufacturing process should be designed to minimize waste and maximize the efficient use of resources. This can involve recycling and repurposing materials and using renewable resources wherever possible.

Additionally, the production process should be designed to minimize the use of water, energy, and other resources to reduce the environmental impact of the operation. Companies should also consider using sustainable packaging materials and reducing the amount of packaging used to minimize waste.

Conclusion

As the CBD industry continues to expand, it is more important than ever for manufacturers to prioritize ethical and sustainable practices in the production of delta-8 and other cannabis-derived products. By prioritizing quality and responsibility at every step of the production process, manufacturers can help build trust and confidence among consumers.