The Challenges and Opportunities of Delta-8 Production in the USA: An Industry Perspective

Delta-8 Production is a topic of growing interest within the hemp and cannabis industry. This is because delta-8 products offer a more potent and psychoactive effect than CBD, which has become increasingly popular in recent years.

The market for delta-8 THC products is growing rapidly, with some estimates predicting it could reach $10 billion by 2025. The main drivers of demand are the potential health benefits, such as pain relief, anxiety reduction, and anti-inflammatory properties, and psychoactive effects.

These effects are said to be milder and less overwhelming than delta-9 THC. However, producing delta-8 THC is not without its challenges, and there are a number of factors that need to be considered.

Delta-8 Gummies – Gold Tropical Mix

Original price was: $82.99.$39.99Current price is: $39.99.

Or Subscribe and Save 30%

Silver Tropical Mix

Original price was: $68.99.$33.99Current price is: $33.99.

Or Subscribe and Save 30%

Understand Delta-8 Chemistry

Delta-8 THC is a minor cannabinoid that occurs naturally in cannabis and hemp plants. It is a close relative of delta-9 THC, which is the primary psychoactive compound in cannabis. Delta-8 THC has a similar chemical structure to delta-9 THC, but it has a double bond on the eighth carbon atom instead of the ninth. This difference in structure means that delta-8 THC has different effects on the body than delta-9 THC.

The process of Delta-8 production involves converting CBD into delta-8 THC. This is done using a chemical reaction that involves the use of a solvent such as ethanol or heptane. The process involves the use of chemicals that can be hazardous if not handled correctly. Therefore, it is essential to ensure that the Delta-8 production process is carried out in a safe and controlled environment.

CBD Manufacturing

CBD manufacturing is a complex process that involves a number of different steps. The first step is to extract CBD from the hemp plant. This is typically done using a solvent such as CO2 or ethanol. The extracted CBD is then purified using a process such as chromatography to remove any impurities.

Once the CBD has been extracted and purified, it can be used as a precursor to producing delta-8 THC. This involves the use of a chemical reaction that involves the addition of a catalyst such as sulfuric acid. The reaction converts the CBD into delta-8 THC.

Opportunities and Challenges While Delta-8 production

Challenges

- Regulatory uncertainty: The legality of delta-8 THC is still murky, with the DEA issuing a rule in August 2020 that could make it a controlled substance. While some states have explicitly legalized delta-8 THC, others have banned it, and there is no clear federal guidance.

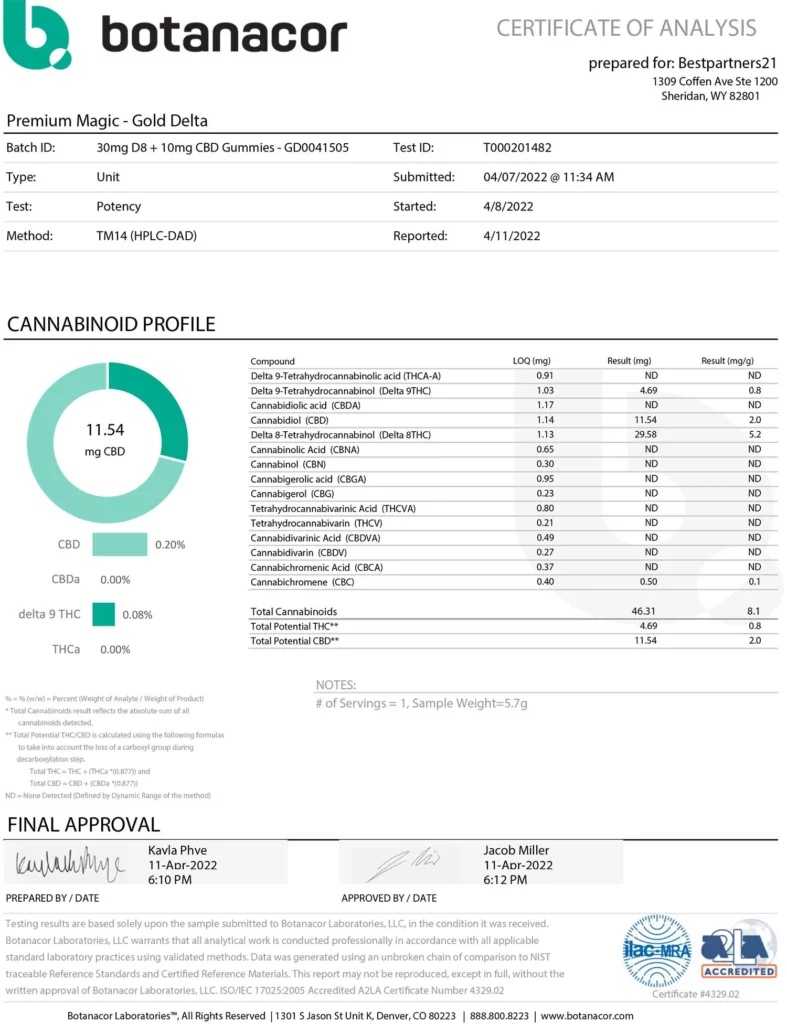

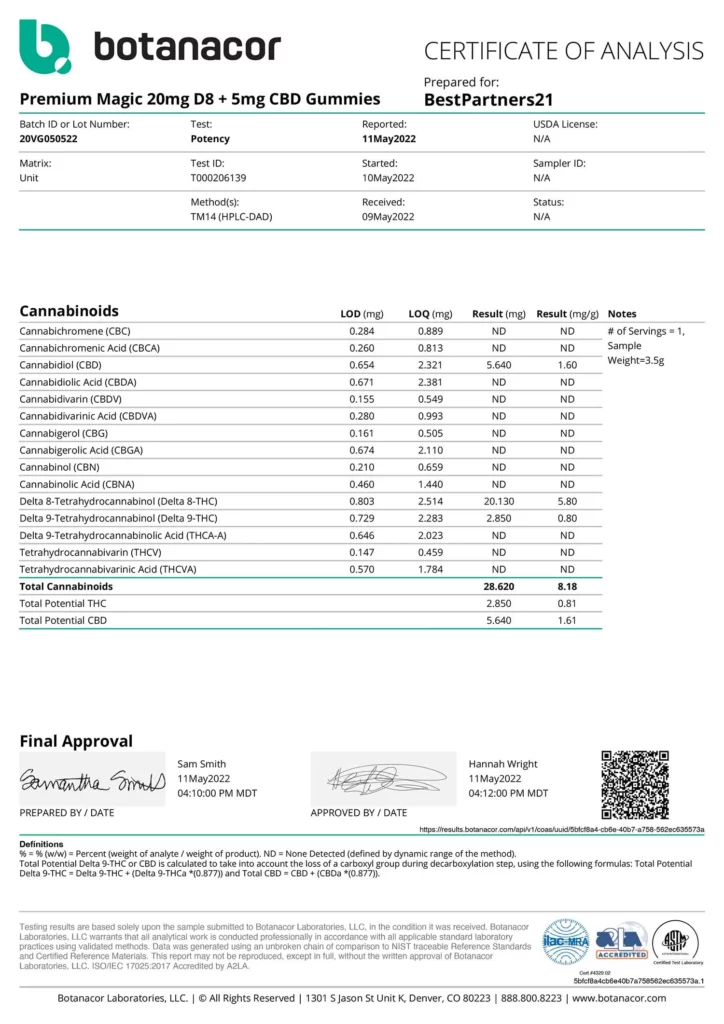

- Quality control: As delta-8 THC is produced through chemical processes, there are concerns about the purity and safety of the final product. Companies must follow strict quality control protocols and third-party testing to ensure that their products are safe and effective.

- Supply chain issues: Delta-8 THC is not naturally abundant in cannabis plants, so companies must rely on synthetic or semi-synthetic Delta-8 production methods. This can be expensive and time-consuming, and there is a risk of supply chain disruptions if there is a shortage of raw materials or other inputs.

Opportunities

Despite these challenges, there are also many opportunities for delta-8 production in the USA. Some of these include:

- Diversification of the cannabis market: Delta-8 THC offers a new avenue for cannabis companies to differentiate themselves and tap into new consumer segments who may be hesitant to try delta-9 THC.

- Lower barriers to entry: As delta-8 THC is not as tightly regulated as delta-9 THC, it may be easier for new companies to enter the market and compete with established players.

- Increased research and development: As delta-8 THC gains popularity, there is likely to be more investment in research and development to explore its potential medical and therapeutic benefits.

How to Make Tetrahydrocannabinol

Tetrahydrocannabinol, or THC, is the primary psychoactive compound in cannabis. It is responsible for the “high” that is associated with cannabis use. There are a number of different types of THC, including delta-9 THC and delta-8 THC.

The process of making tetrahydrocannabinol involves the use of a chemical reaction. This reaction converts the precursor compounds, such as CBD or CBG, into the desired form of THC. The reaction requires careful control of the temperature, pressure, and other reaction conditions to ensure that the correct product is produced.

One of the challenges of producing tetrahydrocannabinol is ensuring that the product is of high quality and purity. This is essential for both safety and regulatory compliance. The Delta-8 production process must be carried out in a controlled environment to ensure that the final product is free from impurities.

Conclusion

Delta-8 production in the USA faces several challenges, including regulatory uncertainty, quality control issues, and supply chain disruptions. However, there are also many opportunities for companies to tap into a growing market and diversify the cannabis industry.

As the legal and regulatory landscape continues to evolve, it will be important for companies to stay up-to-date on the latest developments and ensure that they are following best practices for Delta-8 production and distribution.