Behind the Scenes: The Manufacturing Process of CBD Topicals

CBD, or cannabidiol, is a natural compound found in hemp. Many people use CBD products for wellness benefits. One type of product, CBD topicals, is growing in popularity.

These include creams, lotions, and balms made with CBD. But have you ever wondered how they are made? This article pulls back the curtain on the manufacturing process of CBD topicals. Let’s dive in and explore the journey from plant to product.

What Are CBD Topicals?

CBD topicals are a type of product that allows you to apply CBD directly to your skin. They are crafted by infusing high-quality CBD into a variety of skin-friendly products like lotions, creams, and salves. These products offer a unique way to use CBD, bypassing the digestive system and focusing on specific areas.

Silver Fruity Mix

Original price was: $68.99.$33.99Current price is: $33.99.

Or Subscribe and Save 30%

Silver Paradise Mix

Original price was: $68.99.$33.99Current price is: $33.99.

Or Subscribe and Save 30%

The beauty of CBD topicals lies in their versatility. There’s a wide array of CBD topicals available in the market catering to different needs and preferences. Here are a few common types:

CBD Lotions and Creams: These are popular choices for daily skin care and moisturizing. They often include additional ingredients like aloe vera, shea butter, or vitamin E to enrich the skin. They can also target specific concerns like dryness, aging, or inflammation.

CBD Salves: Salves are typically thicker than lotions and creams. They contain higher concentrations of CBD, making them a good option for people seeking more potent relief from discomfort or inflammation in specific areas of the body.

CBD Balms: Balms are a blend of CBD with waxes and fatty oils. They are often used for targeted relief in specific areas, much like salves, and are typically thicker, providing a longer-lasting layer on the skin.

CBD Beauty Products: The beauty industry is also embracing CBD. You can find it in facial creams, lip balms, mascaras, and more. These products aim to leverage CBD’s potential skin-soothing properties to enhance overall skin health and beauty.

The Raw Material: Sourcing High-Quality Hemp

Every good product starts with high-quality raw materials, and CBD topicals are no exception. The quality of hemp used in the production process determines the overall quality of the final product. Therefore, sourcing high-quality hemp is crucial for creating top-notch CBD topicals.

High-quality hemp should be rich in CBD and low in THC, the compound that causes the ‘high’ associated with marijuana. The hemp should also be free of pesticides and other harmful chemicals that can pose risks to the user.

Sourcing from trusted growers who follow strict farming practices helps ensure the hemp is pure and high-quality. Responsible growers will provide documentation proving that their hemp is organically grown and non-GMO.

Now, let’s take a brief look at how hemp is farmed and harvested.

Hemp Farming:

Hemp is a resilient plant that can grow in various climates. It requires less water than many crops, making it environmentally friendly. Farmers plant hemp seeds closely together, and the plants grow quickly, reaching maturity in about four months.

Hemp Harvesting:

When hemp plants are ready for harvest, the farmers cut down the plants and let them dry. This process, known as retting, allows the plants to dry naturally in the field. After retting, the dried plants are collected for the next step, which is extracting the CBD.

High-quality hemp farming focuses on producing plants that are healthy and rich in CBD. The harvesting process is equally critical, as it can affect the quality of the CBD extracted. The hemp must be dried correctly to prevent mold and other contaminants from spoiling the crop.

Extraction of CBD From Hemp

Once the high-quality hemp is harvested, the next step in the production of CBD topicals is to extract the CBD from the hemp plant. This process requires skill and precision to ensure that the CBD is extracted effectively and without any harmful residues.

There are different methods to extract CBD from hemp, but the most commonly used are CO2 extraction and ethanol extraction. Both methods have their advantages and are chosen based on the manufacturer’s preference and the desired final product.

CO2 Extraction

CO2 extraction is often seen as the gold standard in the industry due to its safety and efficiency. In this method, carbon dioxide is used under high pressure and low temperatures to isolate, preserve, and maintain the purity of the CBD. It requires expensive equipment and skilled operators, but the result is a high-quality, potent, and safe extract.

Ethanol Extraction

The ethanol extraction method uses high-grade grain alcohol as a solvent to extract CBD. It’s a less expensive method and can produce CBD oil at a faster rate than CO2 extraction. However, it can sometimes pull more green coloration and plant matter, which might need additional filtering.

After extraction, the CBD oil undergoes a process known as winterization, especially if the ethanol extraction method is used. This process removes any remaining plant particles, waxes, and fats to produce a clean, pure CBD oil.

Purification and Testing of CBD

After extracting CBD from hemp, the next step is purification. Purification is essential because it ensures that the CBD oil is clean and safe for use. Even with the best extraction methods, the oil can still contain trace amounts of unwanted materials, like chlorophyll or waxes. Purification removes these impurities, resulting in pure and high-quality CBD oil.

But how do you know if CBD oil is really as pure and high-quality as it claims to be? This is where third-party lab testing comes in.

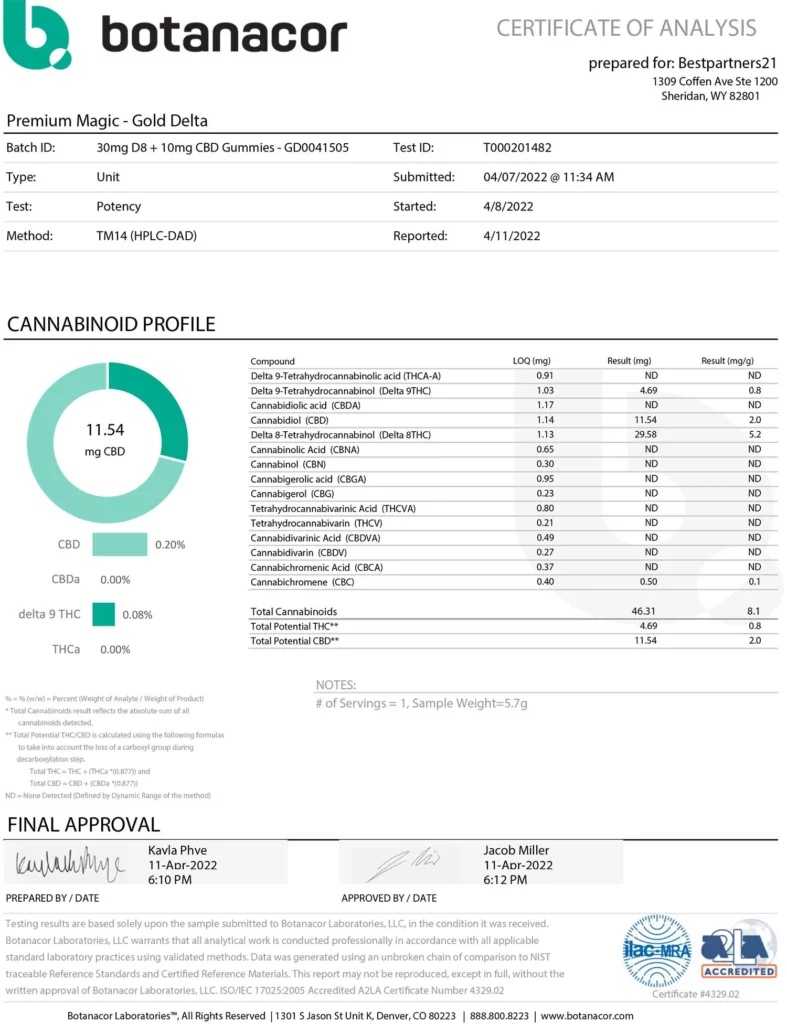

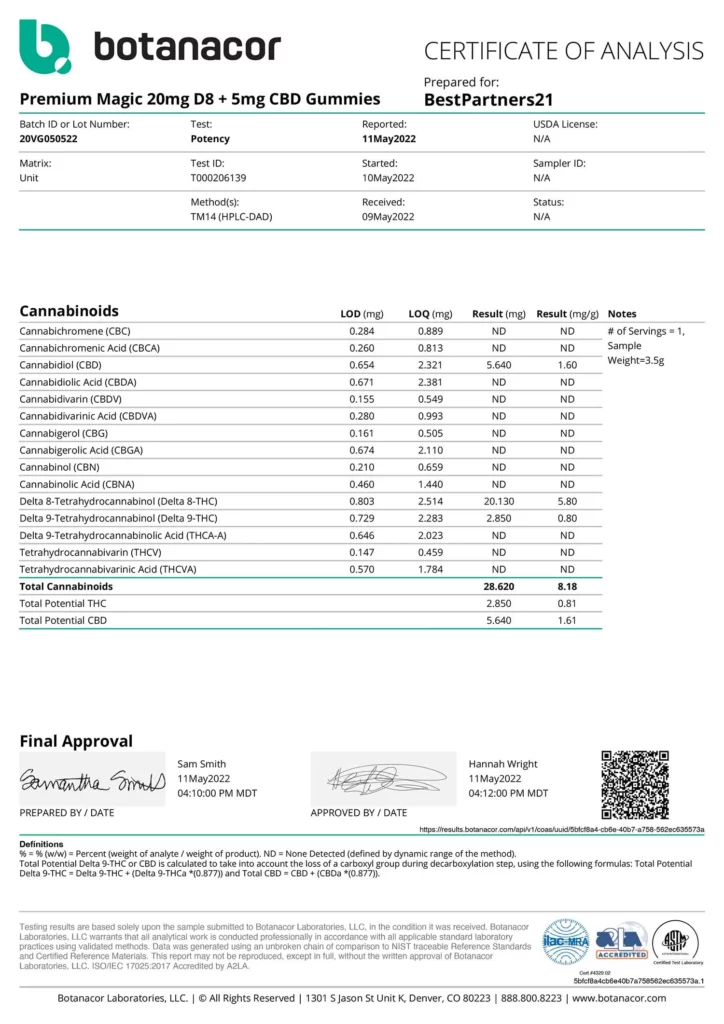

Third-Party Lab Testing

The role of third-party lab testing in the CBD industry cannot be overstated. These independent labs test CBD products to verify their purity, potency, and safety. They check for the levels of CBD and other cannabinoids, the presence of any harmful contaminants like pesticides or heavy metals, and the product’s overall safety.

Formulation of CBD Topicals

With the purified and tested CBD oil at hand, it’s time to transform it into a product you can use on your skin – a topical. The formulation of CBD topicals involves combining CBD with various ingredients like carrier oils, essential oils, and other skin-friendly components.

The Process of Combining Ingredients

The CBD oil is blended with a carrier oil first. Carrier oils help dilute the potent CBD oil and make it easier and safer for skin application. Common carrier oils include coconut oil, jojoba oil, and argan oil. Each of these oils offers additional benefits for the skin, such as hydration, antioxidant properties, and more.

Next, essential oils are added for fragrance and extra therapeutic effects. Essential oils like lavender, eucalyptus, and tea tree oil are commonly used. Then other skin-friendly ingredients like shea butter, aloe vera, and vitamin E may be included for their moisturizing and soothing properties.

The aim here is not just to dilute the CBD oil but to create a formulation that maximizes skin benefits. Therefore, all these ingredients are carefully selected and combined to ensure they complement each other and work together to enhance the effectiveness of the CBD.

Different Formulations for Different Topicals

Just as there are different types of CBD topicals, there are also different formulations for each type. The formulations are crafted to cater to the specific needs and uses of each product. For instance, a CBD lotion for dry skin might have a different formulation compared to a CBD salve for muscle relief. The former might have more hydrating ingredients, while the latter could include ingredients known for their soothing properties.

In essence, the formulation stage is like the recipe stage of making a dish. Each ingredient, from the carrier oil to the essential oils, is carefully measured and mixed to create the final product. This stage is where the magic happens, turning CBD oil into a diverse range of CBD topicals, each with its unique formulation catered to specific needs and uses.

Production and Packaging of CBD Topicals

Once the formulation stage is complete, the final product must be produced and packaged. This is where the formulated mix is filled into containers or tubes, ready for use.

The product is carefully filled into its final packaging, whether it be a tub for a balm, a bottle for a lotion, or a stick for a salve. Packaging isn’t just about appearance; it’s also about preserving the product’s quality. Packaging for CBD topicals should be airtight and light-resistant to protect the CBD from degradation.

Quality Control Measures

During these final stages, quality control measures are crucial. Every product that comes off the production line must be checked to ensure it meets the manufacturer’s standards. This could include checking for correct labeling, ensuring the product is properly sealed, and even sampling the product to ensure consistency and quality.

Manufacturers also have to make sure their products meet legal requirements. For example, labels need to accurately represent what’s inside the product, including the amount of CBD.

Summing Up

Creating CBD topicals involves many careful steps, from growing high-quality hemp to extracting CBD, formulating the product, and finally packaging it. This intricate process ensures that what you apply to your skin is safe, effective, and beneficial.

Knowing how your CBD topicals are made helps you make informed decisions about what products to choose. Always look for products from manufacturers that prioritize quality, transparency, and thorough testing. This way, you can enjoy the benefits of CBD topicals with peace of mind.